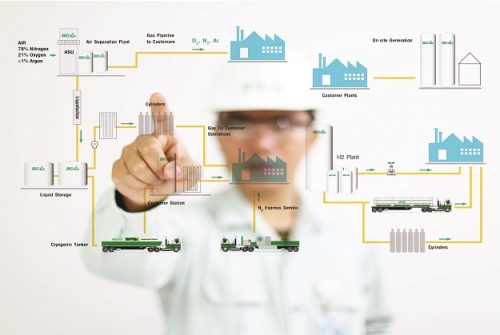

I.Pipeline Supply

YIG supplies Nitrogen, Oxygen, and Hydrogen through its broad coverage pipeline network connected directly to customer’s plants. So far, YIG pipeline supply has been recognized for its supply reliability. YIG’s customers can ensure that their product requirements, even in immediate needs, will be fulfilled by responsive YIG’s professional team supported by our state-of the art logistic system.YIG constantly developed pipeline supply coverage to all the areas in Map Ta Phut Industrial Estate, and expanded further to serve Hemaraj Industrial Estate in Chonburi.

YIG’s pipeline customers includes those who have large-scaled, continuous production processes and are in need of a highly reliable support, such as petrochemicals, refinery, and steel manufacturers.

YIG ‘s professional service team consists of experienced experts engaged in industrial gas pipeline markets. With the full-ranged offerings in pipeline industrial gas, YIG is your first choice for industrial gas pipeline solutions and services.

II. Bulk Deliveries/ Storage Systems

Depending on your gas supply needs, YIG can deliver bulk quantities of nitrogen, oxygen, argon, helium from our production facilities to customers’ sites all over Thailand and some neighboring countries. YIG delivers gas via large and small trucks or trailers with a complete safety system. Liquid gas is filled into high pressure containers to be ready to be filled at customer’s stations later.YIG also has the other delivery mode for hydrogen. YIG’ hydrogen is delivered via “Tube trailer”, an interconnecting high pressure tubes. For all the bulk delivery supply, YIG has international standard logistic system enabling customers to monitor the level of their liquid gas at their stations via our telemetry system to ensure the complete reliability of supply. YIG also allow customers to track their product delivery via our GPS system installed to monitor our vehicle fleets to ensure the total safety of customers’ product.

At YIG, and its parent company, Air Products, nothing is more important than safety. With YIG people’s commitment to total safety through work processes, customers can trust and be confident in YIG’s delivery services.

With strong knowledge and rich experiences in gas applications in various industries, customers always trust YIG technical expert team to design, customize, and install industrial gas stations including tank and pressure systems to fit customers’ needs. With the team’s dedication to provide customers’ solutions and services, YIG is considered an industrial gas supplier of choice for customers in various industries all over the country.

III. Cylinders / Cylinder Packs

YIG delivers gas via cylinder for customers who require small to medium gas volume. For those who require gas in larger volume, we will arrange cylinder pack delivery. The cylinder pack delivery system can be customized to fit each customer’s need both in quantity and type of gas. YIG’s customer service team also provides advice and recommendation to help customers set up appropriate and safe working environment.

IV. On-Site Gas Generator

When your gas requirements are continuous and steady, on-site gas generation can be an economical mode of supply. BIG offers on-site gas generation options for large continuous volume of gases, such as nitrogen and oxygen generators at customers’ sites. Customers using our on-site gas generation solution with YIG can ensure the cost-effective supply option, complete safety standard, as well as higher productivity and lower cost.YIG’s experienced technology teams will work closely with customers to matches production process with their requirements to provide the most appropriate and safest gas generator solutions that meets their needs.

With YIG ’s long experiences, YIG has become a leader in on-site gas generation that has been providing the latest technologies together with safety system to customers in Nitrogen and Oxygen On-site Gas Generators.

V. Temporary / Emergency Gas Services

YIG offers “APEX-Air Products Express Services” solution to customers with urgent needs of large volume of Nitrogen. YIG has its “pumper equipment ”, the mobile station of liquid and gaseous nitrogen pumping system that is ready to serve customers’ urgent requirements at the their plants within 24 hours. Pumper can be used to fulfill the following requirements:

– Reducing temperature in reactor immediately by pumping liquid Nitrogen into the reactor. However, for more than 10 years, YIG has been offering this service to refinery and petrochemical customers in their plant turnaround efforts, and can be proved to help save up to 70% of their turnaround time from that of the regular process.

– Adjusting reactor and drum condition for safety in maintenance. The Nitrogen will be pumped into the reactor to replace hydrocarbon left in reactor and drums. At this point, the level of hydrocarbon is safe to operate the maintenance.

– Removing moist from reactor and drum before plant start- up process by pumping high temperature nitrogen into reactor and drum to replace moist during the maintenance process.

– Performing the leaking test after maintenance processes by pumping high-pressure nitrogen to test if there are any leakages between the connecting points of fixed equipment before the start-up.